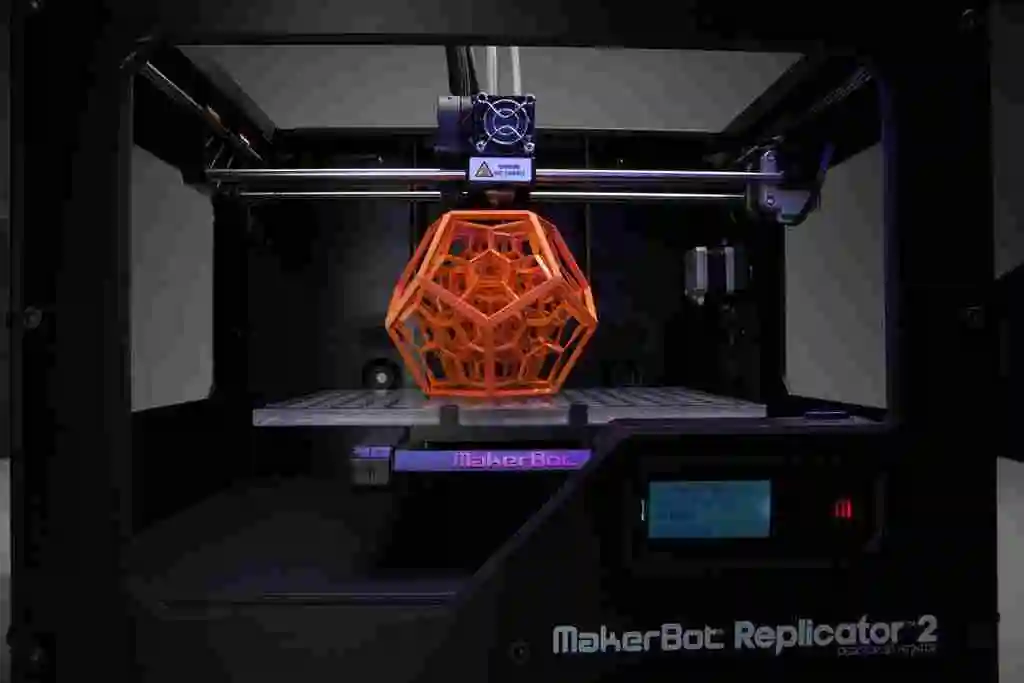

Technologies are advancing at an alarming rate. Things that seemed possible only in science fiction are becoming realities. With this change, comes drastic changes in the industry as well. But, even with new technologies, hazards still exist, and some are even more prone to workplace hazards. One example of this is the 3D printer. This fairly new technology is being used in numerous ways and industries, from auto-mechanics to medical engineering. With it, however, comes a serious hazard.

3D printing generates dust, which is harmless in small amounts, but when collected in large quantities is highly combustible. When a process uses 3D printing on a large scale, they create copious amounts of this dust.

3D printers use a wide variety of materials from plastics, such as nylon and polyethylene, to metals such as stainless steel and aluminum. When this dust accumulates, it creates an explosive hazard. If these particles become suspended in the air and find an ignition source, these particles will rapidly combust, and an explosion occurs. Even materials that, in bulk, are not explosive, can be under the right conditions. Just like any fire, certain conditions need to be met. There needs to be an ignition source, oxygen in the air, and combustible dust acts as the fuel. For a combustible dust explosion to occur, however, there has to a dispersion of dust into the air and a confinement of that cloud. When these conditions are met, the dust will ignite and explode.

These explosions can be catastrophic. In 2017 there were 7 accidents alone, resulting in five fatalities and more injuries. 14 workers were killed in 2008 when a combustible dust explosion occurred in a sugar processing facility in Georgia.

The issue is that, for many industries, dust is inevitable. So, this raises the question, “how can we prevent explosions?” The standards have changed over the past few years. The first is the thorough training of workers. Teach them how to recognize hazards and how they can correct them. Routine housekeeping and installment of dust collection systems will avoid the build-up of these deadly dusts around your facility. Making sure that you dust control equipment has an explosion suppression system or oxygen deficient atmosphere is recommended.

There are more ways that you can learn to control explosive hazards in your workplace. If proper steps are taken to avoid dust accumulation and regulations followed, you can protect your workers, and yourself, from the hazards presented with combustible dust. As always, good luck and stay safe.

For safety training please visit us at our website at www.hardhattraining.com