Lockout/tagout is the practice of using an energy isolating device to stop machines and equipment from moving unexpectedly during maintenance. But the term “lockout/tagout” clearly refers to two distinct methods. In fact, lockout and tagout procedures do vary both in how they look and when they should be used. If you work with or around heavy machinery, it’s important to know the difference the difference between lockout and tagout.

Differing Devices

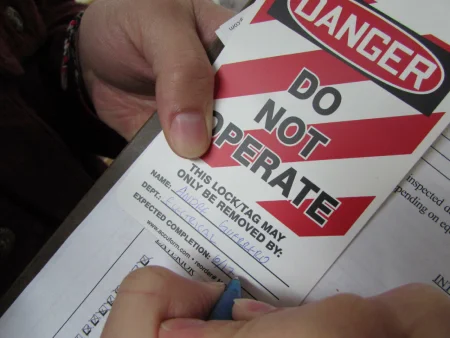

Both lockout and tagout procedures begin by putting an energy isolating device (like a circuit breaker, line-valve, or block) to guard the energized parts of the machine. From there, the employee performing the maintenance fits the energy isolating device with either a lockout or tagout device.

Lockout devices physically lock the energy isolating device. The only way to remove it is with a key or some other means of disengaging the lock. Lockout devices are the safest and sturdiest option. They help make sure that no one activates the machine, even accidentally.

Tagout devices have no physical locking mechanism. They are simply highly visible tags attached to the energy isolating device that warn employees not to use the machine undergoing maintenance. Unlike lockout devices, tagout devices cannot prevent someone from removing an energy isolating device. While they do offer some amount of protection, they aren’t as inherently safe.

When to Use

When considering lockout/tagout procedures, you should use lockout devices whenever possible. They ensure that the equipment will remain de-energized for as long as is needed. In situations where using a lockout device would be impractical or unsafe, however, you should at least attach a tagout device to remind employees to stay away.

In all cases, OSHA requires that lockout/tagout devices be installed only by employees who have been trained and authorized to do so. Lockout/tagout devices must stay attached until the equipment is safe to operate again, and may only be removed by the employee who installed them.

Lockout Tagout: Vital Procedures

Lockout tagout is a practice that is often overlooked. Closing down a machine may seem like enough, and sometimes it may be. However, there are times when the machine needs more attention than just that. This safety practice is put in place to protect employees and everyone that may be near the machine. Take a look at this accident on ehssafetynewsamerica.com that occurred because of the lack of lock-out tag-out:

“Lockout Tagout (LOTO)” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities.

Approximately 3 million workers service equipment and face the greatest risk of injury if lockout tagout is not properly implemented. alignment with the lockout tagout standard (29 CFR 1910.147) prevents an estimated 120 fatalities and 50,000 injuries each year. Workers injured on the job from exposure to hazardous energy lose an average of 24 workdays for recuperation. In a study conducted by the United Auto Workers (UAW), 20% of the fatalities (83 of 414) that occurred among their members between 1973 and 1995 were attributed to inadequate hazardous energy control procedures specifically, lockout tagout procedures.

LOTO is addressed in specific standards for the general industry, marine terminals, longshoring, and the construction industry.”

Although it may not seem like a big deal, the use of lockout tagout can be the difference between life and death. These standards are put in place in order to keep workers safe and free from harm. alignment to these standards can prevent serious injuries and fatalities. It is important for you and those around you to be well trained in lockout tagout, and to know the proper procedures surrounding this standard. Training can save money, time, and even lives.

Lockout-Tagout; Life Saving Procedures

Of all the deaths that happen in the construction industry, how many of them do you think are preventable? While there may not be an exact number to answer that question, there have at least been several that could have been prevented with proper lockout-tagout procedures.

Lockout-tagout (LOTO) refers to specific practices and procedures which are set in place in order to safeguard employees from the unexpected startup of machinery and equipment, or the release of unexpected hazardous energy. If lockout-tagout is not properly implemented, workers face a great risk of injury; especially the nearly 3 million workers who service equipment that must be locked out. If LOTO procedures are followed and implemented, an estimated 120 fatalities and 50,000 injuries could be prevented each year. In a study done by the United Auto Workers, they found that 20% of the fatalities that occurred among their members between 1973 and 1995 were attributed to energy control procedures, specifically lockout-tagout.

In relation to this procedure, a man was killed at a Clearwater Paper mill in Ladysmith, Wisconsin. The machine operator was killed while servicing a high-speed conveyor belt. OSHA says his death was “preventable.” He was apparently killed because his employer did not ensure that the equipment on which he was working was properly powered down and locked out. During an investigation, it was found that mill employees often work under high-speed conveyors, and other equipment, while still in production mode. This leaves employees exposed to machines pulling them in, striking them, or creating other hazards. OSHA’s area director, Mark Hysell, said “This man’s death is tragic and was preventable. Despite incidents like this one, machine hazards continue to be one of the most frequently cited federal worker safety violations. It takes just minutes to stop and put safety first.”

We are in agreement with Hysell; make sure to always take the extra time to put safety first, as it may save at least one life.

Lockout/Tagout Case Study

With all of the accidents happening in the news, sometimes it’s hard to pick out exactly what went wrong. Was it a lockout issue? Was it lack of training? Was it just plain negligence? Read the following true case study, and see if you can decipher what went wrong.

CASE STUDY: A maintenance worker was on a ladder changing a ballast in an overhead light fixture, approximately 6 feet off the ground. While attempting to change the ballast, the worker sustained an electrical shock, and fell off the ladder. The worker was hospitalized, and later died from his injuries. What went wrong?

Unfortunately this is an accident that actually occurred in June of 2016. This accident could have been prevented with just a few simple steps. The first problem in this case study is the lack of lockout tagout safeguards. The worker was doing maintenance on a light fixture, which exposed him to electrical hazards. This company did not provide proper training on lockout tagout practices and procedures, and required them to change ballasts without this training. This means that workers were unable to properly disable machinery or equipment in order to prevent hazardous energy release. Had this company provided lockout tagout training, or had the proper lockout safeguards on the electrical hazard, this worker may not have been shocked, and may not have fallen to his death.

An additional mistake is the lack of safety in regards to the ladder. While it may be a minor thing, this worker should have had some kind of fall protection, or some other kind of safety measure that would have prevented him from falling off of the ladder.

Any safety violation can be detrimental. While it may not seem like a big deal, even lockout tagout procedures, or ladder fall protection can save a life.

Lockout/Tagout, and the Rule To Change the Game

OSHA has recently been re-publishing rules that they think will change the safety game of construction. The idea is that they take out unnecessary, outdated, or inconsistent rules, and modernize them, based on what they have seen in investigations. One rule change in particular, the lockout/tagout rule, might prove costly to employers, as before, employers could work around the rule. However, taking one word out of the lockout/tagout rule could make a big difference in the way companies run.

“A One-Word Change To Lockout/Tagout Rule

OSHA’s Lockout/Tagout rule lays out standards required by employers to protect workers from potentially hazardous energy sources while working on equipment. Under the current rule, machines must be disconnected from energy sources when “unexpected” energization of the equipment could result in injury.

OSHA seeks to remove “unexpected” from the Lockout/Tagout standard because employers have been effectively defending themselves from citation and penalties based on that one word.

If there are warning devices such as alarms and lights that precede equipment energization, then it wouldn’t be unexpected, and according to the present rule, would not require Lockout/Tagout procedures.

OSHA Wants To Overturn A Court Ruling

OSHA has been hamstrung by a court case two decades ago in which it argued the Lockout/Tagout rule applies if injuries could occur from unintended startup of a machine, even if there was a warning of such startup.

However, the 6th Circuit U.S. Court of Appeals ruled that the word contained in OSHA’s Lockout/Tagout standard, “unexpected,” means there must be an element of surprise. If a machine is designed not to start without alerting workers, then there is no surprise, and therefore no requirement to follow the Lockout/Tagout standard.

OSHA says removing the word “unexpected” from the rule would eliminate confusion about rule applicability, and would be better aligned with the agency’s original intent for the rule. However, removing the word “unexpected” from the rule would essentially overturn the 6th Circuit U.S. Court of Appeals’ decision.

From a pure safety perspective, removing the word “unexpected” would undoubtedly be safer for workers as more machines would be required to be locked and tagged appropriately. The argument from employers is with OSHA’s attempt to sneak this change in without due process and formal rulemaking.

OSHA’s standards and improvements project, by it’s own admission, is intended to make updates with insignificant cost or burden on employers. If a company has invested in ensuring equipment is specially outfitted not to start unexpectedly, removing “unexpected” from the Lockout/Tagout rule could pose a significant adverse affect on operations and costs on employers, which should require OSHA going through the rulemaking process.”

If you’re looking to train or become certified in lockout/tagout procedures, the newest version of our lockout/tagout training is available here.

The following training materials can be found on our website: