When it comes to older models of vehicles, it can be difficult to find parts for it. This can lead to searching through many junk yards until you are lucky enough to stumble upon a used part. The thing is, there may be a way to make this search easier, and that way can be through the efforts of 3D printing.

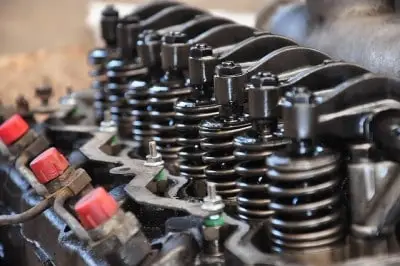

3D printers have progressed since their invention in the 1980s. They started with resin progressing to plaster, plastic, and now metal. With their progression, people have been able to utilize it and build parts for older models of vehicles, starting with plastic and now metals, such as aluminum or a mix of aluminum-silicon.

Dailmer, with Mercedez-Benz, has been utilizing 3D printers by printing off spare parts for older commercial trucks and has now been branching further into using metal as the source to create these 3D parts. In a Digital Trends article, they spoke to Daimler about his use of metal 3D printing by saying, “Daimler claims the 3D-printed parts are just as strong as the die-cast aluminum versions installed on the trucks when they were new…That makes it perfect for producing spare parts, which are usually only ordered in small batches.”

Another company, Vadar Systems, created a 3D printer that uses molten metal to build their parts. Dailmer uses a format of using aluminum-silicon powder and melting it down with a laser, while Vadar Systems’ model takes sheets of aluminum metal, and melts it down into molten form and ejects droplets onto a moving plate. In an article from PCWorld, they wrote that this process is twice as fast as other printers and operates at 90 percent of the cost. They also mentioned, “That differs from other metal printers, which lay down a layer of powdered metal and melt it with a laser or electron beam, a process called powder bed fusion. In this process, there’s a chance that some particles of the powder do not get melted, creating weak spots.”

There are many different 3D printing styles, and many more are still emerging. We are excited to see what these companies do with this technology, and how it will affect the industries that use it.

For More Info: hardhattraining.com